Contact

Zhejiang Vlead CNC Technology Co., Ltd

Tel: +86-18025806868

E-mail: michael.qiu@vlead.ltd

Linkedin: vlead-machinery

facebook: VleadMachinery

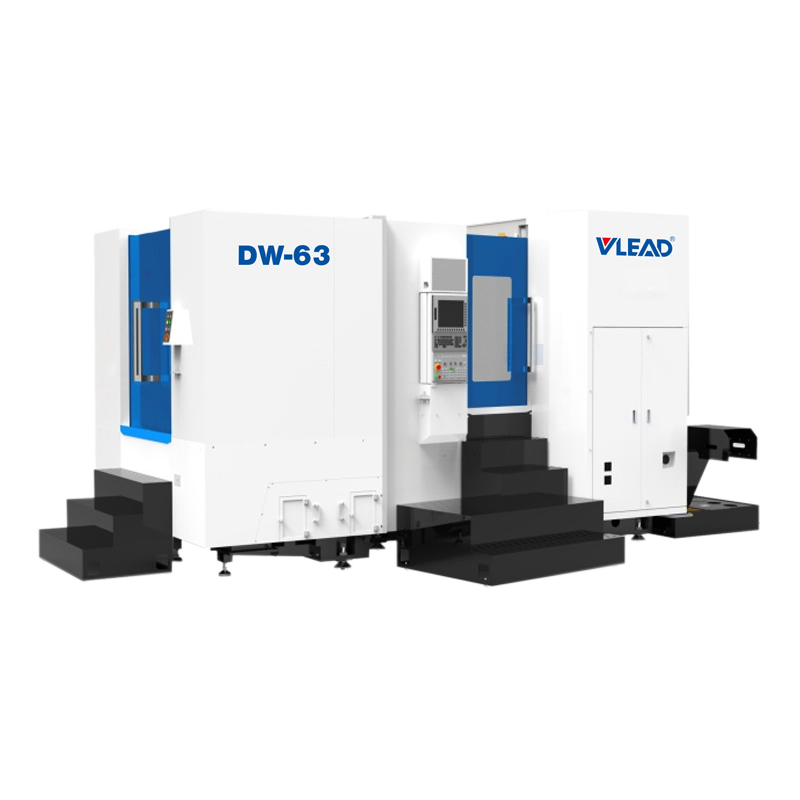

Products

·Has many advantages such as high speed, high precision, and high strength in performance

·Excellent and efficient ability to process key components

·Can easily handle materials such as aluminum alloy, fire alloy, and high-temperature resistant alloy

·Fast processing speed, good rigidity, and highly automated processing equipment

·Complete multiple processes such as milling, praying, drilling, and tapping in one clamping process

·Suitable for processing box type parts such as aerospace, automotive parts, shipbuilding, electronics, etc

Long bar parts machining center

·Specially designed for metal cutting of elongated components

·Very space saving

·High efficiency machining center

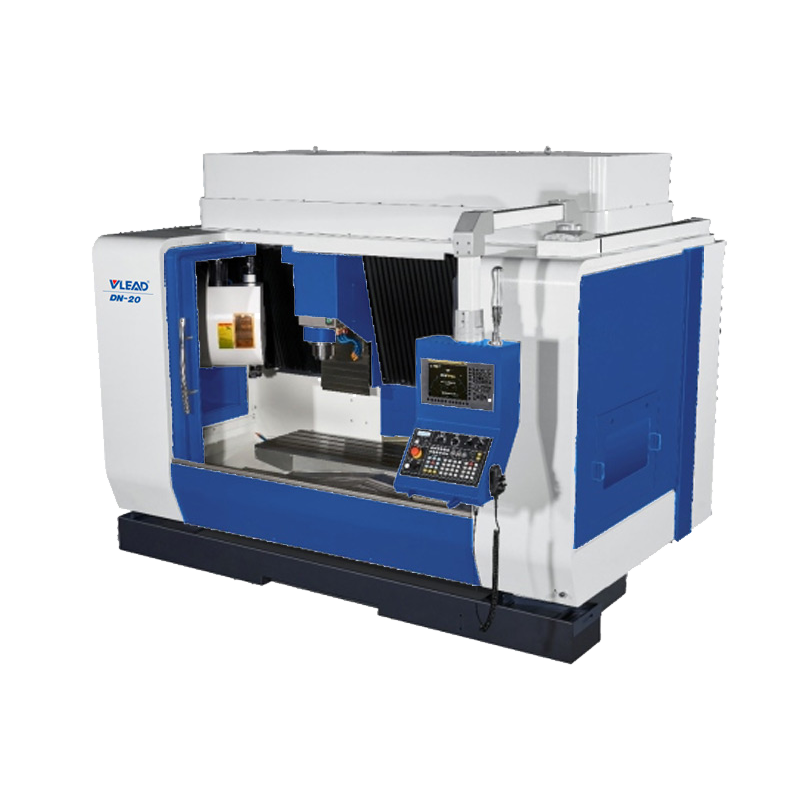

·Specially developed for precision machining of large components and molds

·The design of the gantry bed enhances the load-bearing capacity and stability of the workbench

·Reduce the distance between the spindle and the column rail surface, and improve cutting rigidity

Engraving and milling machining center

·A mature model in the door structure series

·Specially designed for precision small components

·Stable machining accuracy and extremely high spindle speed

High speed drilling and machining center

·Efficient processing performance

·Compact space design

·The best choice for processing small and complex components

·Specially designed for processing product components, molds, etc

·Strong cutting force and high performance

·Quickly and reliably replace cutting tools